Solar cells packing with wodden case

1. Solar cells packed with carton box 2. Boxes sent into the wooden case 3. the inner boxes of the whole wooden case

Loading pallets of solar cells to the container

1. 40 FEET HIGH CONTAINER 2. LOADING WITH FORKLIFT FOR SOLAR CELLS 3. SOLAR CELLS IN THE CONTAINER

spot price

Wafer (Unit: pc) Item High Low Average price Change(%) Change($) Multi Wafer - Diamond Wire (USD) 0.154 0.15 0.152 -- -- Multi Wafer - Diamond Wire (RMB) 1.15 1.08 1.12 1.8 0.02 Mono Wafer - 158.75mm / 175µm (USD) 0.306 0.297 0.304 -3.2 -0.01 Mono Wafer - 158.75mm / 175µm (RMB) 2.42 2.26 2.38 -4 -0.1 Mono Wafer - 166mm / 175µm (USD) 0.317 0.312 0.315 -3.1 -0.01 Mono Wafer - 166mm / 175µm (RMB) 2.51 2.42 2.47 -3.9 -0.1 Quotes for mono-Si wafers are based on low-resistance ones. The price quotes for mono-Si wafers are based on 175-um wafers. Thinner wafers are calculated according to the formula. Cell (Unit: W) Item High Low Average price Change(%) Change($) Multi Cell - DW - 18.7% (USD) 0.092 0.057 0.061 -1.6 -0.001 Multi Cell - DW - 18.7% (RMB) 0.496 0.457 0.489 -2.2 -0.011 Mono PERC Cell - 158.75mm / 21.9%+ (USD) 0.142 0.093 0.1 -- -- Mono PERC Cell - 158.75mm / 21.9%+ (RMB) 0.82 0.77 0.79 -- -- Mono PERC Cell - 158.75mm Bi-facial / 21.9%+ (USD) 0.142 0.093 0.1 -- -- Mono PERC Cell - 158.75mm Bi-facial / 21.9%+ (RMB) 0.82 0.77 0.79 -- -- Mono PERC Cell - 166mm / [...]

Module price competition intensifies as capacity ramps continue

Polysilicon Polysilicon prices for mono-Si wafer stayed flat this week. The trading price of some producers increased marginally by less than RMB 1/kg, sitting at around RMB 58-60/kg and RMB 59/kg for average. Overall, polysilicon manufacturers are attempting to raise price for July orders, but they are biding their time as mono-Si wafer prices are expected to decline and some manufacturers are still filling June orders. At present, some downstream manufacturers are conservative about price increase. Moreover, inventories overall are maintained at a certain level and supply will become stable as polysilicon producers that are under maintenance program are gradually resuming operation, polysilicon price for mono-Si wafer are therefore projected to rise marginally in July. However, the real market price depends on the acceptance of downstream segments. The price trend is expected to become clear after the Dragon Boat Festival. Demand for polysilicon for multi-Si wafer is picking up as end markets gradually recover. The downstream companies are purchasing slightly more polysilicon for multi-Si wafers than the previous weeks. Manufacturers that had been focusing on multi-grade polysilicon production began to produce more mono-grade polysilicon through modifying techniques recently. With supply of polysilicon for multi-Si wafer gradually decreasing, prices of such product [...]

210mm high power modules bring down LCOE further

Following Trina Solar’s launch of modules featuring 500Wp+, several Chinese manufacturers also unveiled high-power modules based on different wafer sizes, accelerating the transition to grid parity. With cell efficiency hitting bottleneck, utilizing larger wafers to drive LCOE down and efficiency up has become a trending topic. While solar costs continue to drop, global end-user demand has room for growth. Capacities in the wafer, cell, and module segments are sufficient to fulfil demand for products based on 180-210mm format. In response to the shift of wafer sizes, manufacturers are gearing up for adopting 210mm format in their new capacities, and this means they have determined the size for the next five to ten years. Therefore, this year saw many solar companies adopting different sizes of wafers for their newly launched high-power modules, opening up to an era for 500Wp modules. Global demand forecast for 2020 Since the beginning of March, overseas markets have been suffering from the COVID-19 pandemic and governments across the globe have been busy preventing the virus from spread. It’s foreseeable that 2020 is a tough year for overseas markets. As foreign markets are now recovering, the higher-than-expected shipment volumes to Europe suggests that the impact on European markets [...]

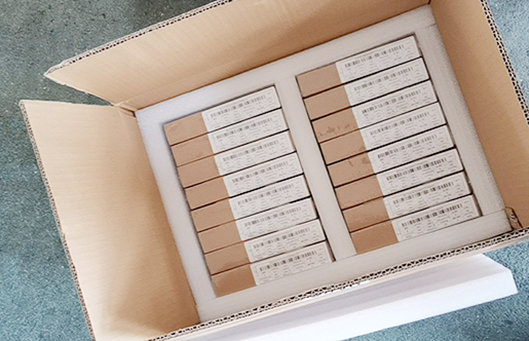

Identification and prevention of mirco-cracks in PV modules

Photovoltaic modules micro-crack, hot spot, PID effect are three important factors affecting the performance of photovoltaic modules. Today, we will take you to understand the cause of the photovoltaic modules micro-crack, how to identify and prevention methods. I. Formation and classification of cracks in photovoltaic modules Micro-cracking is a common defect of photovoltaic modules, namely, some invisible micro-cracks.Due to its own crystal structure, crystalline silicon solar modules are prone to fracture.In the production process of crystal silicon module, many links may cause the cell sheet to crack.The root causes of fissure: External force: The solar cells will be subjected to external force in the process of welding, laminating, framing, handling, testing, etc., and will cause hidden cracks when the parameters are improperly set, equipment failure or improper operation. High temperature: the solar cells sheet has not been preheated at low temperature, and then it will expand in a short time after suddenly meeting high temperature, which will cause cracking phenomenon. For example, the welding temperature is too high, the laminating temperature and other parameter Settings are unreasonable. Raw materials: The defects of raw materials are also one of the main factors leading to cracking. According to the shape of the hidden crack, the cell [...]

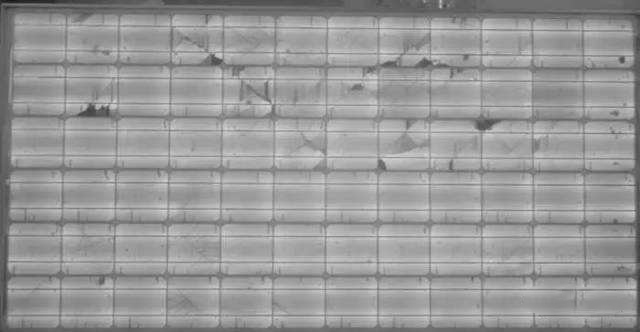

Why the wafer is getting more bigger and bigger?

With the development of technology, the size of monocrystalline silicon wafer is increasing. Before 2012, the size of monocrystalline silicon wafers was mainly divided into two types: 156mm margin and 125mm margin. At the end of 2013, longi, Zhonghuan and other five major manufacturers took the lead in unifying the silicon wafer size with a standard of 156.75mm At the beginning of 2020, Longi, Zhonghuan introduced large silicon wafers with the sizes of 166mm ,182mm and 210mm respectively. The reason is that the increasing size of silicon wafers can bring many aspects of cost reduction and efficiency increase for all downstream links. The large silicon wafer cost reduction mainly comes from the below two factors: Capacity is increased after wafer bigger ,the corresponding equipment ,labor cost do not need to increase . Solar cells production line production rate to be calculated by pieces.when wafer’s area is larger, the capacity increases, the corresponding expense as labor cost,equipment deprecition is decline. M12 than M2 solar cells can save USD013 /W, drop 25.6%.It also happened on production of solar modules. From the side of solar modules and power station, after the size of wafer and solar panelincreases, the consumption of frame ,PV ribbon,EVA etc increases correspondingly, but the increase is less than benefits come from bigger wafer. Large wafers [...]