Photovoltaic modules micro-crack, hot spot, PID effect are three important factors affecting the performance of photovoltaic modules. Today, we will take you to understand the cause of the photovoltaic modules micro-crack, how to identify and prevention methods.

I. Formation and classification of cracks in photovoltaic modules

Micro-cracking is a common defect of photovoltaic modules, namely, some invisible micro-cracks.Due to its own crystal structure, crystalline silicon solar modules are prone to fracture.In the production process of crystal silicon module, many links may cause the cell sheet to crack.The root causes of fissure:

External force: The solar cells will be subjected to external force in the process of welding, laminating, framing, handling, testing, etc., and will cause hidden cracks when the parameters are improperly set, equipment failure or improper operation.

High temperature: the solar cells sheet has not been preheated at low temperature, and then it will expand in a short time after suddenly meeting high temperature, which will cause cracking phenomenon. For example, the welding temperature is too high, the laminating temperature and other parameter Settings are unreasonable.

Raw materials: The defects of raw materials are also one of the main factors leading to cracking.

According to the shape of the hidden crack, the cell can be divided into five types: tree crack, comprehensive crack, oblique crack, crack parallel to the main grid line, perpendicular to the grid line and through the whole solar cells.

II. the impact of “hidden crack” on solar modules performance

The current generated by solar cells is mainly collected and exported by the main grid line and the thin grid line which are perpendicular to each other on the surface.Therefore, when the hidden crack (usually parallel to the main grid line) leads to the fracture of the fine grid line, the current cannot be effectively transferred to the main grid line, which will lead to the failure of part or even the whole solar cells sheet, and may also cause debris, hot spot, etc., and also cause the power attenuation of the solar modules.

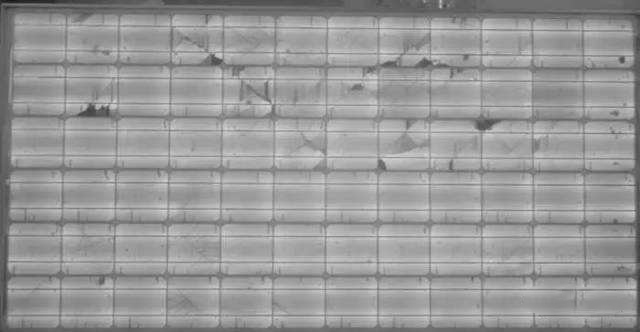

III. the identification of “Micro-crack” method

EL (Electron luminescence) is a kind of internal defect detection equipment of solar cells or solar modules, which is a simple and effective method of detecting hidden cracks.Based on the Electron luminescence principle of crystalline silicon, the near-infrared image of solar modules is captured by high-resolution infrared camera, and the defects of solar modules are determined.It has the advantages of high sensitivity, fast detection speed and intuitive results.The following figure shows the detection results of EL, clearly showing various defects and cracks.

IV. the formation of “micro-crack” reasons

There are many factors causing component micro-crack and there are many types of micro-crack, but not all of them will affect the solar cells, not to mention the “hidden” color change, as long as the scientific prevention can be appropriate to avoid the solar modules of micro-crack.In the process of production, the solar cells should be avoided by improper external intervention, also pay attention to the storage environment temperature range.During the welding process, the solar cells should be kept warm in advance (hand welding). The temperature of the soldering iron should meet the requirements.In the process of component production, transportation, installation and maintenance, considering the cracking characteristics of solar modules, it is necessary to pay attention to and improve the operation process in each process of installation power station to minimize the occurrence of component hidden cracks